Kirtland AFB Discovered Leaking Jet Fuel Earlier Than 1999 Then Failed to Investigate and Remediate

Report Prepared for Citizen Action New Mexico by Dave McCoy, Esq.,Executive Director July 2013

Kirtland Air Force Base spokespeople and Pentagon Air Force top brass have repeatedly misinformed the public and media about when problems at the Bulk Fuels Facility (1) were first known. Documentation of waivers for pipeline testing, obtained under the Freedom of Information Act, reveal that the AF knew much earlier than 1999 that jet fuel was leaking at the fuels facility, that the pipelines could not meet safety requirements and needed repairs/replacement.

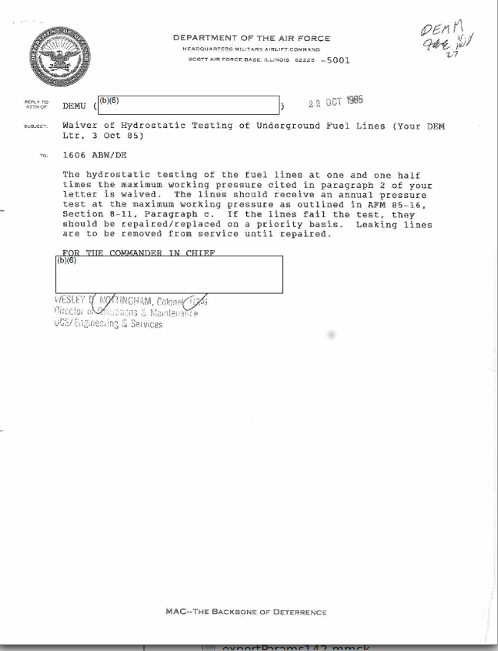

- In 1985 Kirtland knew fuel facility pipeline tests would fail if conducted. The AF issued a waiver for the 5 year pressure test because the pipelines did not meet AF requirements. Pipelines were not repaired and annually tested as ordered in the waiver.

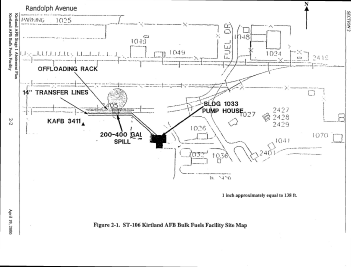

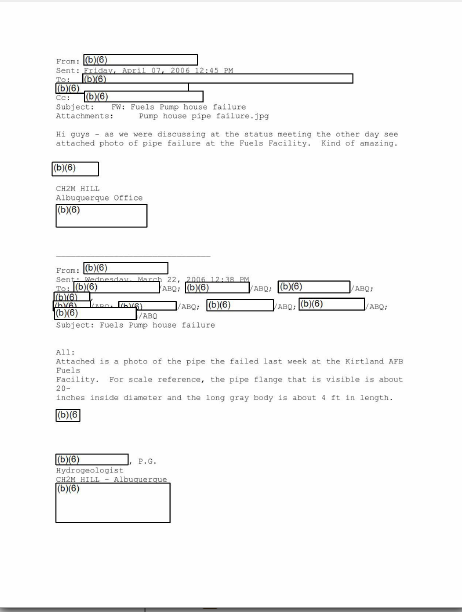

- The Air Force knew the fuel facility was leaking in 1992 (3) from a location identified as pump house Bldg 1033 and from contamination at a nearby evaporation pond; other pipelines were leaking elsewhere at Kirtland. (See pgs: 3-5).

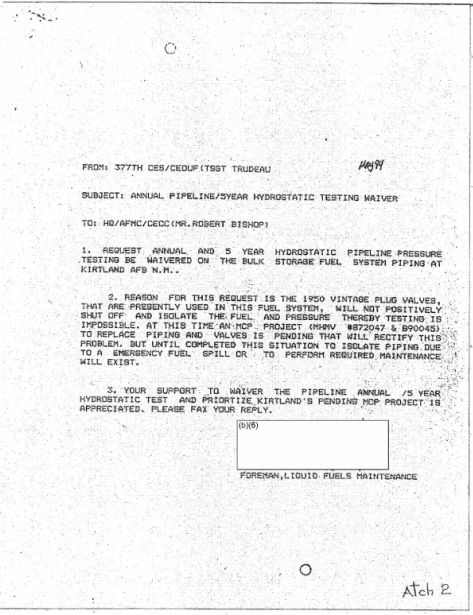

- In 1994 the AF issued waivers for both the 5 year pressure test and the annual pipeline testing because it was known that pipeline valves would fail. Replacement and repair of defective valves and piping was not done. The 1994 waivers described pipeline testing as “impossible.” (See p. 3 and 5 year hydrostatic testing waiver).

- Kirtland’s claim that it did not know the aquifer was contaminated until 2007 is false.

- Kirtland knew from a feature on a 1951 aerial photograph that the historical fuel offloading/dispensing location showed soil contamination.

- Soil levels of diesel fuel were so high at the fuels facility offloading rack (ST-106) that the risk of an explosion existed from drilling monitoring wells.

- Kirtland has repeatedly not complied with New Mexico Environment Department orders to determine the magnitude of the leak, how far and how fast it is traveling. (See pgs: 3-4, 8, 9-10).

- Kirtland has no plan or actions to clean up the dissolved plume of contamination, but has embarked on a public propaganda campaign that “Albuquerque drinking water remains unaffected by the fuel plume and is expected to remain so indefinitely.” That scenario can only be accomplished, however, if municipal wells are shut down or the drinking water is treated. Treatment facilities do not currently exist at the Ridgecrest municipal well locations.

- Albuquerque’s municipal wells, Kirtland’s supply wells and the Veterans Administration Hospital supply well are all at risk from the spreading plume of contamination of Ethylene Dibromide, a potent carcinogen. Military personnel, sick veterans and residents receive water from these wells. (See pgs: 2, 4).

- Albuquerque’s plans for furnishing another 400,000 people with water are unrealistic and improbable given drought and contamination of 30 square miles of groundwater at other Albuquerque locations.

page 1

The Agency for Toxic Substances and Disease Registry 2013 report has inaccurate conclusions and recommendations based on inadequate data and errors. (See p. 12).

Kirtland failed to conduct an early and complete investigation into the leaking at the bulk fuels facility, missing an opportunity to remediate and halt the spread of a massive plume of aviation gas and jet fuel contamination that is now estimated at 24,000,000 gallons, the largest toxic spill into a public water supply in U.S. history.

Mark Holmes, an Air Force project manager with Kirtland’s environmental unit stated in 2000, “I don’t think personally we’re going to find that much (that spilled).”

Kirtland dragged its boots by not comprehensively investigating the integrity of the entire fuels facility for many decades and remained conveniently silent about early internal reports showing pipeline problems. In its FOIA response, Kirtland could provide no evidence whatsoever of compliance with AF pipeline and inspection requirements (4) in force prior to 1985. After the knowledge and waiver of pipeline defects in 1985 and leaking in 1992, more than a decade went by before Kirtland inspected the underground pipelines connecting the fuels facility pump house to the offloading rack. This allowed the additional release and spreading of hundreds of thousands of gallons of jet fuel that could have been prevented.

Had Kirtland extended its investigation from the facility’s leaking pump house to the fuels facility offloading rack (p 11) that were both connected by underground pipes, perhaps 20 years of the spreading off base plume of jet fuel and a 6000 ft long plume of dissolved Ethylene Dibromide (EDB) could have been prevented. Ethylene Dibromide is an exceptionally potent carcinogen (p. 1) with high solubility, mobility and persistence in groundwater. EDB also has been found to be carcinogenic to fish (Hawkins et al. 1998). In addition to being carcinogenic, EDB causes neural tube damage in rat embryo culture (Brown-Woodman et al. 1998), and has been implicated in liver and kidney damage, and reproductive lesions such as reduced sperm levels (p. 4: Scharder et al. 1988).

Kirtland neglected for decades to make the five year pipeline integrity tests (4) that federal law and Air Force regulations required. Kirtland exhibited negligence per se (6) in contaminating Albuquerque’s drinking water aquifer by ignoring and violating Air Force and federal regulations, New Mexico statutes and non-compliance (5) with environmental clean up orders.

One of Kirtland’s excuses, recently concocted, for missing the largest jet fuel spill in history, is that the vacuum pipelines that sucked fuel to the pump house from the offloading rack were supposedly exempt from inspection. Kirtland made certification under 40 CFR 270.11, which provides for criminal penalties, that the information was true, accurate and complete. The AFM 85-16 requirements for annual and 5 year inspections of pipelines applied to:

"All Air Force operated above and underground fuel piping systems at transfer operations, pumping and in-plant processing operations.” (Emphasis supplied).

page 2

Kirtland has provided no evidence -- in the references for the July 2011 work plan nor evidence of any written waivers in the Administrative Record or in the FOIA response -- to support or justify the failure from the 1950s until 1985 to inspect the pipelines as was required at the time by Air Force Manual 85-16 (7). Five year hydrostatic pipeline pressure tests and annual pipeline inspections were required by Air Force Manual 85-16.

A waiver for testing the fuels facility pipelines at Kirtland was issued based on known pipeline defects in 1985. (See attached waivers here, here, here and here) Evidence obtained under the Freedom of Information Act reveals that on October 22, 1985 Col. Wesley Nottingham, AF Director of Maintenance and Operations issued a waiver for the 5 year hydrostatic testing of the fuel lines (at 1½ times operating pressure). The waiver ordered the continuance of annual pipeline testing with repair/replacement on a priority basis. “Leaking lines are to be removed from service until repaired.” Since it is admitted by KAFB that the lines were leaking for decades, it is evident that at least the annual inspections and repairs were not performed as required in the waivers.

In June 1994 two separate waivers were granted – one for the 5-year hydrostatic test and one for the annual test requirements because the piping and valves could not be tested:

“The reason for this request is the 1950 vintage plug valves that are presently used in this fuel system, will not positively shut off and isolate the fuel and pressure. Thereby testing is impossible. At this time an MCP project to replace piping and valves is pending that will rectify this problem. But until completed this situation to isolate piping due to a[n] emergency fuel spill or to perform required maintenance will exist.”

The requirement that “Lines with known leaks or repair requirements should be repaired prior to testing,” was contained in the 1985 and 1994 waivers. No repairs were made. Kirtland did not perform a hydrostatic pipeline test (at 150% of operating pressure) at the fuel facility offloading rack until 1999. Although the fuel facility was installed in the 1950s, Kirtland claims it did not test the integrity of the pipelines for decades even though federal law required testing every five years. When Kirtland tested the fuel supply lines in 1999, pressure was lost in seconds and some 200-400 gallons of jet fuel spilled into the ground from the two, 48 year old, corroded pipelines #22 and #23. The so-called “small spill” was from Kirtland’s own testing and did not encompass the volumes already released before testing.

The three types of fuel handled by pipelines at the BFF were aviation gas (AvGas; high-octane gasoline), Jet Propellant-4 fuel (JP-4), and JP-8. The use of AvGas and JP-4 at Kirtland AFB was phased out in 1975 and 1993, respectively. The presence of all three fuels in the soil shows that the leaking occurred for decades without investigation.

Soil samples taken in 1992 around pump house Bldg #1033, which was part of the bulk fuels facility, showed “the presence of elevated concentrations of petroleum hydrocarbons and associated compounds” that exceeded environmental limits up to 3600 times (p 3.1). The pump house was about 275 ft distant from the offloading fuel rack and the areas were connected by fuel pipelines for the supply of fuel (7).

In the early 1990s Kirtland was pumping between 20-25 million gallons of fuel per year. The soil area was visibly contaminated around pump house building #1033. In 1993 the area of the pump house was identified as a solid waste management unit (SWMU ST-341) that federal law required investigation. This information should reasonably

page 3

have caused Kirtland to fully investigate its entire fuel facility. Federal and state law required Kirtland to determine the rate, direction and the distance that such spills travel. Until 1999, Kirtland took no steps to sample the nearby soil at the bulk fuels offloading rack area or the pipelines that delivered the fuel to the nearby pump house.

Kirtland was aware from visual observation and samples taken in 1992 and more than 100 soil samples taken during 1994 through 1996 that leaking was occurring in the vicinity of the pump house from a condensate holding tank and an evaporation pond (9). Seven years supposedly passed (10) before Kirtland investigated or reported whether leaking was occurring around the fuel offloading racks to where the pipelines extended from the pump building.

Boreholes were only drilled 12 ft deep (11) near Building #1033. There were “data gaps” (p. 18-4) for knowledge about the horizontal and vertical extent of the contamination.iv The U.S. Environmental Protection Agency (EPA) identified high levels of gasoline and diesel contamination in 1998 and stated that Kirtland needed to specify the depth to groundwater and provide more environmental information (12) about the ST-341 pump house site.

Kirtland’s claim that it did not know the aquifer was contaminated until 2007 is false (13). In 2006 Kirtland learned from skimmer pumps that the jet fuel plume was off base at Bullhead Park. However, the contamination of groundwater from jet fuel, including Ethylene Dibromide, was known as a threat to “receptors,” i.e., the municipal wells, five years earlier, as shown by an internal Kirtland April 1, 2002 memorandum:

“Contamination exceeding WQCC standards was detected in the subsurface soil to a depth of 300 fbgs with a real extent of 6-7 acres. Contamination has been detected in the groundwater beneath the site at a depth of 480 fbgs, 180 feet below the vertical extent of the contamination, which also exceeds WQCC standards. The groundwater contamination was caused by downward diffusion & the soil gas to the water table. (Emphasis supplied)

… “The extent of the contamination is significant and continued corrective action is required. The Relative Risk Evaluation is High based on groundwater contamination and identified receptors.”

The Veteran’s Administration Hospital supply well is nearest to the EDB plume. It lies approximately 1200 feet north of the fuels facility offloading rack and a little more than 500 ft west of the EDB plume. In 2006 monitoring well KAFB-1064 was constructed in the VA parking lot, 200 ft away, to serve as a “sentinel” monitoring well upgradient of the VA Hospital’s production well. TPH-DRO, TPH-GRO, toluene, naphthalene, phenanthrene, nitrate, dissolved iron, and dissolved manganese were detected from the very first groundwater sample.

KAFB currently has shut down supply wells KAFB-15 and KAFB-16 and is not sampling them for contamination, reportedly for excessive NOx emissions and pump failure, respectively. A bent valve was found in a cylinder of the #16 pump and the cost to repair the problem is around $30,000. “Mr. Wilson had stated during his ride around inspection that he didn’t want to spend any more money on Well 16 since it is also the highest arsenic level Well KAFB operates.”

page 4

The Air Force knew in the 1980s that spills and leaks were commonplace at Kirtland and other bases and highly toxic to drinking water. Kirtland began review of waste generation sources, including the Fuels Management areas in November 1981. Underground tanks were pressure tested quarterly to find unseen leaks. Hundreds of contaminated sites were identified by the EPA at Kirtland in the 1980s and 1990s. For example, an Underground Tank Storage (UST) pipeline for intermittent vehicle refueling at a different Kirtland site had tightness tests performed in September and October 1991; results indicated that the product line from UST 58 was in a state of failure. (pgs. 4-22) News articles in 1987 raised the issue that UST petroleum storage was a contributor to contamination at Mountain View. EPA called for sampling and hydrology evaluations to address the Mountain View problem. Chemicals still remain today in the soil and aquifer at Kirtland dumps, burn pits, explosive sites, labs, radioactive training sites, septic lines, underground tanks, radioactive animal carcass pits. The Agency for Toxic Substances Disease Registry identified the problem existing at Air Force bases (15).

Kirtland also abandoned a buried 8-inch fuel line (ST-108) that supplied Aviation Gas and JP-4 to the refueling area from the pump house. The ST-108 fuel line was originally part of the Kirtland AFB Bulk Fuels Facility installed in approximately 1953. That pipeline was part of the bulk fuels facility, 4500 ft long, and was more than 40 years old. A total of 915 gallons of fuel was later pigged and drained from the buried pipeline. It was discovered according to this document (16) “During site preparation for the construction of a new fire station at Kirtland.”i The date of the fire station construction is not given. Use of the buried line was discontinued sometime in the 1980s.

Another version of the ST-108 pipeline: “The distribution station and a section of the southern portion of the fuel line were removed by the City of Albuquerque (COA) during taxiway construction for the Albuquerque International Sunport in 1993.” And: “The period of operation of the fuel line is not known, and no records exist that document either the partial removal by the COA or any tightness testing of the line.” (See sec. 4.1.1, p. 52)

The observable stained surface soil at the ST-106 offloading rack in 1999 was from an area approximately 25 ft by 75 ft. The ground was “saturated” (See sec. 4.1.1, p. 52) with fuel so the staining did not just occur overnight and would have been observable well prior to 1999. Approximately 76 cubic yards of soil was excavated and disposed offsite in November 1999 after “discovery” of the release.

Kirtland found that the soil levels of diesel fuel were so high at the bulk fuels facility (ST-106) that the risk of an explosion existed from drilling.

“Concentrations of contaminants in the vadose zone reached 100% of the lower explosive limit during drilling activities. This required changes to drilling techniques to minimize explosion risks. Also detected were vinyl chloride in soil gas, necessitating additional health and safety precautions.”

page 5

For Kirtland authorities not to have known of the spill prior to 1999 requires that fuel facility personnel were blind, had no sense of smell, or were completely indifferent to a large area of soil that was visibly stained and saturated from decades of leaking jet fuel, and; that they utterly failed to perform their regulatory duties for inspection, keeping inventory, clean up, spill prevention and response, annual reports, sampling, testing, ongoing communication with other personnel, workplace safety evaluations, emergency planning, and safety exercises.

Under AF guidelines, the Key Compliance Personnel who had numerous duties to perform to keep a fuel facility safe includedi:

- Base Environmental Protection Committee (EPC). The EPC is usually responsible for drafting and reviewing the spill prevention and response (SPR) plan prior to its promulgation by the Base Commander and for the annual review and update of the SPR plan. Often, the EPC delegates the specific preparation of the plan to the Base Civil Engineering (BCE) for implementation by the Base Environmental Coordinator (EC). The EPC also is responsible for review and implementation of the Base Plan for recoverable and waste petroleum.

- Spill Response Team (SRT). The SRT is tasked to respond to spills when requested by an On-Scene Commander (OSC) and to perform spill containment, recovery, cleanup, disposal and restoration activities as directed by the OSC. The SRT is a multidisciplinary team often including the following persons: BCE, Base Environmental Coordinator, Bioenvironmental Engineer (BEE), Base Disaster Preparedness Officer (BDPO), Fire Chief, Security Police Chief, Public Affairs Officer (PAO), Base Fuels Flight Commander, Safety Chief, and Staff Judge Advocate (JA).

- Base Fire Department. The fire department provides support in emergency response, spill events, exercises, and fire protection activities. In addition, the department will be responsible for making periodic fire safety inspections of flammable or combustible storage and handling areas, hazardous waste storage areas, and accumulation points on the installation.

- Safety Manager. This individual is responsible for conducting workplace safety evaluations and inspections of the handling and storage of hazardous materials and waste. They will provide the appropriate manager with a report of their findings and recommended corrective actions. They are also responsible for ensuring the prompt and accurate investigation of any hazardous material mishaps that result in injury or property damage.

- Base Fuels Management Officer (BFMO). The BFMO is responsible for the safe and efficient receipt, storage, handling, issuing, and accounting of all petroleum products to include all general operations and inspections.

- The Base Civil Engineer (BCE). The BCE is responsible for the maintenance of all installed petroleum storage and dispensing systems. This responsibility often is discharged by the Liquid Fuels Maintenance (LFM) shop. The BCE also is responsible for the calibration of permanently installed meters.

- Base Environmental Coordinator (EC). The EC monitors all POL activities that may affect the environment and usually is responsible for the coordination of the EPC review and updates of the SPR plan. The EC also often coordinates the reportable spills notification of appropriate Federal and state agencies on behalf of the Base OSC. Generally the EC comes under the BCE.

page 6

- The Bioenvironmental Engineer (BEE). The BEE takes samples to determine the chemical nature, pollutant concentration, and extent of each reportable quantity spill as required for response actions and documentation.

- The Base Disaster Preparedness Officer (BDPO). The BDPO is responsible for emergency planning and training of installation disaster response forces. When appointed as Emergency Planning and Community Right-to-Know Act (EPCRA) coordinator, the BPDO will exchange emergency response plans with the LEPC and participate in LEPC meetings.

Could these above personnel all have failed to perform their duties, not provided written reports or observed what amounted to decades of leaking aviation gas and jet fuel? An environmental assessment team reviewer with written questions and a checklist was tasked with: reviewing records for spills; interviewing the above fuel facility personnel for compliance with applicable standards, and; inspection of the fuels facility to see that there was compliance with environmental regulations that included:

“Verify that a file of Federal and state POL, Spill Prevention, Control, and Countermeasures (SPCC) plan (Spill Prevention), and Oil and Hazardous Substance Pollution Contingency (OHSPC) plan Regulations are maintained and kept current at the installation"(...):

- Executive Order (EO) 12088, Federal Compliance With Pollution Standards (1978).

- 33 CFR 153, Control of Pollution by Oil and Hazardous Substances, Discharge Removal.

- 40 CFR 110, Discharge of Oil.

- 40 CFR 112. Oil Pollution Prevention.

- 40 CFR 279, Standards for the Management of Used Oil.

- 40 CFR 300, National Oil and Hazardous Substances Pollution Contingency Plan.

- Air Force Instruction (AFI) 23-201, Fuels Management.

- AFI 23-502, Recoverable and Unusable Liquid Petroleum Products.

- AFI 32-7044, Storage Tank Management.

- AFM 85-16, Maintenance of Petroleum Systems.

- Technical Order TO 35-1-3, 36-1-3, 37-1-1, 42B-1-1, 42B-1-23, and 00-25-172.

- Applicable state and local regulations.

- Verify that the Base Staff Judge Advocate reviews Federal, state, and local regulations that may affect ongoing and proposed activities and keeps the EPC informed as needed.

- Verify that the installation has an appointed Fuels Environmental Coordinator.

In November 1999 Kirtland informed NMED that fuel facility personnel “recently contacted” Kirtland Environmental Management about the line spill.i No date for when personnel first contacted EM was given. What were fuel facility personnel doing in relation to the fuels facility for the decades before 1999? Could it have been reported earlier? Was it reported earlier but just deliberately ignored? The offloading rack was in regular use and the area would have been observed on a recurring basis. The Kirtland memorandum informed NMED (p. 1):

“Environmental Management was recently contacted by personnel of the KAFB Fuels Management Facility after they observed stained soils at the facilities' offloading rack. EM staff went to the site and instructed site staff to dig down to determine if the staining indicated more than just a surface spill event. The ground was found to be saturated with fuel.” (Emphasis supplied).

page 7

And this, from NMED GWQB dated 7/20/2000 (p 2, #3):

"KAFB must determine the full vertical and horizontal extents of the JP-8 discharges reported in November 1999. Especially in the area of pipelines #22 and #23, sampling only along the pipeline may not be sufficient to define the full 3-D extent of the contamination. The reason for this condition is to comply with 20 NMAC 6.2.4106.C.2a."

As of Dec. 31 2013, this has not been done.

Kirtland surmised there could have been an earlier history of the lines leaking: (p. 38)

“The primary below ground transfer pipeline (pipeline #22) had been in a state of failure for an unknown duration and therefore the total amount of fuel released is unknown.”

Upon testing Pipeline #23 the second time,

“product visibly bubbled from the ground.”

Both of the 48-year old pipelines “failed from corrosion” within seconds of the pressure testing.

Just how Kirtland accounted for fuel inventory and loss is unexplained and conflicting. The Air Force required fuel management accounting (p. 2/3),including metering, for decades before Kirtland’s unexplained lack of records:

“To prevent fraud, theft, and misappropriation, the organization commander manages, controls, and accounts for all fuel issued to and received in their organizational tanks.”

The quantity for each tank was to be determined and a record of it kept on file for auditing purposes.

Kirtland inventory records for the one year prior to the “spill” showed JP-8 fuel loss of 97,171 gallons for pipeline #22. However, in a November 2000 addendum to its Abatement Plan, Kirtland claimed that inventory records were only kept from 1996 forward and showed a loss of 157,353 gallons of JP-8 for a 5-year period but with no records for JP-4 fuel (pgs. 1, 2). The earlier investigation of the pump house and evaporation pond (ST-341) were later described as being “pertinent” to investigation of the pipeline leak (ST-106). Also, see this. (17)

NMED’s Ground Water Quality Bureau (GWQB) informed Kirtland (18) in July 2000 that its Abatement Plan for sampling only along pipelines #22 and #23 would not be adequate to determine the full horizontal and vertical extent of the contamination.

In 2000 Kirtland claimed it would only need to spend $400,000 (19) investigating the missing 157,000 gallons. Ten years later on May 22, 2010, former NMED Secretary Curry announced that the cost of cleaning up the fuel leak could top $100 million. But that cost estimate was made when it was believed the leak was 8 million gallons, not the triple-sized 24 million gallon gusher estimated in 2012. The magnitude of the spill and the spread of the plume of EDB might have been significantly reduced (20) had the pipelines been tested on the five year schedule.

After decades of purportedly failing to inspect the bulk fuels facility‘s components, in 2012 Kirtland could confirm with conviction (pgs. 1, 2) its ignorance about the source(s) and timing for the jet fuel and aviation gasoline spills:

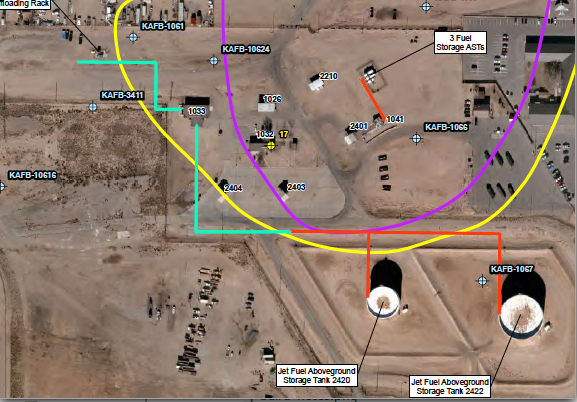

“The exact history of releases is unknown. Conceptually, releases could have occurred when fuel was transferred from railcars, through the fuel offloading rack (FFOR), to the Pump House, and then to the bulk fuel storage containers on the south end of the site (aboveground storage tanks [ASTs] 2420 and 2422).”

In 2002 NMED again criticized the investigation of the pump house contamination (ST-341) as being inadequate (21) for the plan to locate the bottom of the plume of contamination.

page 8

Perhaps the concept of “plume boundaries” related to differing source areas of contamination at Kirtland and Sandia Labs needs re-examining. Should the concept instead be more along the lines of “contamination without borders?” A total of more than 560 sites of contamination were identified at Sandia Labs and Kirtland in the presence of a very large and mobile aquifer.

Despite Sandia Labs and Kirtland’s possession of some of the most powerful computers in the world, no real time three-dimensional model for the aquifer and contamination movement exists at present. Groundwater analysis by boreholes and monitoring wells has not been adequate to convey a full picture of the complex relation between past and present contamination and potential transport between all the various sites where releases occurred at Kirtland and Sandia Labs.

In 2004 CH2M Hill estimated that the prospects for bioremediation of the jet fuel were “not significant (22):”

“Because of the depth of the contamination, the lack of oxygen, and the lack of moisture in much of the Kirtland AFB subsurface soils, the reduction in contaminant concentrations by biodegradation would not be expected to be significant (USAF, 200l b).”

Despite insignificant prospects for bioremediation, in March 2011, the Air Force Report to Congressional Committees was that:

“Using natural processes without further active treatment, modeling indicates that the dissolved constituents would meet drinking water standards by 2025.”

Of course that modeling estimate was made before NMED announced that the spill is three times as large as it was thought to be in 2011. NMED later informed Kirtland that EDB does not naturally biodegrade (p. 2). Estimates for the arrival time of EDB at the municipal wells is between less than 5 to 10 years. Maps for the extent of the EDB plume are only drawn to show where the EPA drinking water limit is (50 parts per trillion), not where the laboratory limit of detection is (10 ppt). This makes the EDB plume map appear smaller than it really is.

Beginning in 2004, Kirtland claimed that soil vapor evaporation (SVE) technology would clean up any remaining contamination at the bulk fuels facility within 3 years with no further action necessary (p. 37, Sec. 6.1.2). Between 2004 and 2009, Kirtland only installed four SVE units, an insufficient number of units for the area of contamination. As explained above, Kirtland knew in 2002 that the jet fuel was already in the aquifer. Kirtland misinformed the public that SVE technology would solve the problem, despite EPA statements in 1994 that SVE could only treat unsaturated zones (p. 6) and was not effective treatment for diesel fuels and ethylene dibromide that do not readily volatilize.

In 2009, the NMED Ground Water Quality Bureau (GWQB) demanded that Kirtland take remediation activities at the “soonest practicable juncture.” The GWQB rejected Kirtland’s plan for a three-year delay (23) after investigation to commence the full-scale abatement of off-base remediation of dissolved ground water contamination. NMED also disapproved (24) of the phased approach to implementing an interim measure to contain the fuel plume and

page 9

directed the Air Force to install 16 SVE wells with internal-combustion engine (ICE) vacuum units to contain the fuel plume. Kirtland refused to operate more than the original 4 SVE units that were at times placed inefficiently or shut down for months and with deferred maintenance. The four units were indefinitely shutdown in December 2012.

On April 2, 2010, the GWQB transferred the jet fuel spill to the Hazardous Waste Bureau (HWB) harshly admonishing Kirtland (pgs. 1/2) that:

“KAFB has not complied with the requirements of the GWQB's first and second Notices of Deficiencies (NODs). KAFB has failed to provide an interim work plan with specific dates for task completion, or a revised timeline that provides for the investigation and abatement of off-base plumes in a reasonable time frame. Additionally, KAFB's December 30, 2009 letter indicates that it will not be moving expeditiously to begin active remediation of off-base contamination. Given the scope and severity of the contamination plume, KAFB's proposed approach is not acceptable.”

The orders of the HWB have been largely ignored as well (25). The Air Force ignored four NMED orders beginning in April 2, 2010 to produce an Interim Measures (IM) Work Plan that would bring about full remediation of the LNAPL plume within 5 years. No IM plan providing remediation other than the use of SVE has been submitted by the Air Force. A plan for a containment well was only partially approved by NMED (p. 7) because it could make the plume travel further toward the northeast where municipal wells are located:

“NMED staff said that the light non aqueous phase liquid (LNAPL) containment well that was drilled to stop the forward movement of the fuel product floating on the water table have been delayed due to some concerns raised at the NMED that the wells may act to pull the LNAPL plume further downgradient, rather than halt its movement. NMED staff told the board that the three concerns they have for the status of this site is the data gap that exists for the extent of the dissolved phase plume, the existence of ethylene dibromide (EDB) above the drinking water standards at all depths, and the evidence of a “diving” EDB at the farthest reach of the dissolved phase plume."

The first off base monitoring wells were not drilled until 2010, eighteen years after leaking was discovered at the fuels facility. Three new clusters of monitoring wells installed northeast of the EDB plume in 2012, have not detected contamination. Some see that as a hopeful sign and count on many more years before the EDB plume may reach municipal wells. However, the plume is still moving at an unknown velocity. Monitoring Well KAFB-10615 detected ethylene dibromide (EDB) in 3rd Quarter 2012 sampling at a concentration of 0.075 micrograms per liter (μg/L); that is 1½ times the EPA drinking water limit. That monitoring location, which lies southeast of Gibson and Louisiana, signals a possible widening of the EDB plume to the east by nearly 1000 ft. A lithographic depiction of monitoring wells from the 4th Q Report shows the presence of EDB at the outer toe of the plume at a 100 ft depth that is attributed to the “pull” of the Ridgecrest municipal wells. The flow velocity of the plume will continue to accelerate as it draws nearer to the municipal wells. The flow velocity still has not been calculated, according to NMED. (p. 5, item 6).

page 10

Shaw Environmental is informing regulators and the public in 2013 that the LNAPL plume is “stable.” NMED isn’t buying the stability story and points to the conflicting language in Kirtland’s own technical reports saying that “stability” doesn‘t mean the plume isn‘t still moving. NMED further challenges Kirtland’s claims (p.2, item A) about bioremediation of the plume and states:

“The fact that EDB is not naturally attenuating or biodegrading indicates that this particular compound is not part of a stable plume.”

Shaw reported that the jet fuel became trapped beneath a rising water table due to conservation efforts. The trapped jet fuel will be “an ongoing source of dissolved groundwater contamination indefinitely.” (p. 31)

The Albuquerque Bernalillo County Water Utility passed resolutions in 2012 seeking to accelerate the timetable to December 2013 for producing a plan for remediation.

Now, 20 years after discovering contamination at the fuel facility, Kirtland still has not determined the flow velocity nor the full lateral and vertical extent of the dissolved plume of ethylene dibromide that has traveled more than 6000 feet from the fuel facility toward Albuquerque‘s municipal wells (26). Nor has Kirtland offered any comprehensive work plan to remediate or halt the spreading plume of cancer-causing ethylene dibromide headed for Albuquerque‘s municipal drinking water wells.

Kirtland’s continuing mantra that it “owns the problem” provides no real relief, especially since the Air Force only sees a duty to keep the level of contamination in the drinking water below the maximum limits imposed by the EPA. Because EDB is classified as a probable human carcinogen, as a matter of public policy, EPA sets the recommended level at zero. The allowable limit in New Mexico is 50 parts per trillion but only 10 ppt in California and Massachusetts. Why should residents feel secure if the water only contains 49 parts per million of EDB at the tap?

The challenge that the best remediation companies seem to have with the Kirtland site is addressing the contractual relationship with the Air Force. These companies are unwilling to engage in a pay for performance contract with the Air Force. The contracting terms are too uncertain and the cost to apply for one of these contracts is unreasonable. Hence the public gets second rate companies, as Shaw Environmental, now acquired by CB&I, has proven to be.

Reference

1) Comprehensive Site Evaluation (p. 14) of Bulk Fuels Area, September 2004. “The ‘Bulk Fuels Facility’ refers to a group of buildings, piping and associated appurtenances used to store and transfer jet fuel from tankers and rail cars to the flight line at Kirtland AFB. The JP-4, JP-8, and AVGAS were pumped from the tanker trucks through the offloading rack (Building 2405) to a pump house (Building 1033) under suction via two 14-inch-diameter underground transfer lines. The fuel was then pumped under pressure to the above ground storage tanks through underground and above ground piping of varying diameters.”

2)FINAL NON-WASTE LINE INVESTIGATION WORK PLAN May 1994, p. 16-1:

“During a previous base environmental compliance and monitoring program inspection, a spill was observed near the UST standpipe. In December 1992, Kirtland AFB Compliance and Assessment personnel collected a soil sample near the suspected spill area. The sample was analyzed according to EPA Methods 8020 and 418.1 and contained petroleum hydrocarbons, ethylbenzene, toluene, and xylenes. The site was revisited on March 3, 1993 by Kirtland AFB personnel. Shallow soil samples (6 to 7 inches below grade) were collected at four locations in the spill area. Hydrocarbon odors were noted at all sample locations and Kirtland AFB personnel reported a small area of surface soil contamination around the base of the UST Stand pipe and extending a few feet west. Based on this information and previous analytical results, the Condensate Holding Tank was added as a SWMU to the RCRA Part B Permit.”

3) 3/9/2007 NMED letter to Carl J. Lanz, P.G., (p. 2, Item 3).

“A plan to assess soil contamination near the historical fuel offloading/dispensing feature identified in the 1951 aerial photograph nearest the KAFB-1065 well …”

4) AFMAN 85-16, Maintenance of Petroleum System, 15 March 1956, 18 August 1981. Superseded by AFMAN 32-1275, UNIFIED FACILITIES CRITERIA (UFC) OPERATION AND MAINTENANCE: MAINTENANCE OF PETROLEUM SYSTEMS Section 2.3 Maintenance of On Base Pipelines. “2.3.3.2. Five-Year Hydrostatic Test. Perform a hydrostatic pressure test every five years on all underground fuel transfer pipelines (product is typically the test media for this test).”

See AFM 85-16 requirements (download only): The Environmental Compliance Assessment and Management (ECAMP) Supplement for The Environmental Assessment Program and Management (TEAM) Guide, p. 8-15:

“Air Force operated offsite pipelines should be inspected at least once per week by air patrol, and once a year by line walker or vehicle patrol. All Air Force operated above and underground fuel piping systems at transfer operations, pumping and in-plant processing operations should be managed according to specific parameters. All underground aviation fuel transfer pipelines should be subject to a hydrostatic pressure test on a 5-yr reoccurring basis.” (Emphasis supplied).

5) Historical Overview of New Mexico Ground Water Protection Programs, Maxine Goad, p. 36-37 -- Burden of proof is upon discharger to demonstrate discharge would not pollute the groundwater. See also Bokum Resources Corp., et. al. v. New Mexico Water Quality Control Commission, no. 2869 (Ct. App. 1978).

6) Clark v. United States No. C85-97TB (660 F. Supp. 1164) (W.D. Wash. April 20, 1987) McChord AF base held liable for negligence and emotional distress for TCE contamination of drinking water wells. TCE leached from AF golf course in Washington. AF negligence caused diminution in value of plaintiff’s property. See also NMED documents here, here and here.

7) Light Non-Aqueous Phase Liquid (LNAPL) Containment Interim Measure Work Plan Part 1 Characterization Plan Bulk Fuels Facility Spill Solid Waste Management Units ST-106 and SS-111 July 2011(p.3-2):

“Fuel transfer from the rail cars to the Pump House was done under vacuum transfers. Transfer of fuel from the Pump House to the bulk storage containers was performed under pressurized conditions. Fuel-transfer infrastructure for vacuum transfers was exempt from pressure testing, whereas fuel infrastructure for pressurized transfer did undergo regular pressure testing. Only when the vacuum portion of the fuel system underwent pressure testing in 1999 was any problem noted in the fueling system.”

8) Stage 1 Abatement Plan ST-106, Kirtland AFB Bulk Fuels Facility, April 19, 2000, p.2-4:

“Diesel range organics (DROs) (5.2 to 2,000 mg/kg) were detected in 12 samples and gasoline range organics (GROs) (0.22 to 360,000 mg/kg) were detected in 16 samples. The NMED action level (100 mg/kg) was exceeded in nine samples by DROs and six samples by GRO.”

“A condensate holding tank, designated as SWMU ST-341, is located at Building 1033, which is the pump house building associated with ST-106 [the fuel offloading rack]. Several RCRA investigation phases have been conducted at the ST-341 site and data from these investigations is pertinent to the overall investigation of ST-106.”

9) INTERIM FINAL RCRA FACILITY INVESTIGATION (RFI) GUIDANCE May 1989, p. 76: procedures designed to verify suspected releases (if necessary), and to evaluate the nature, extent, and rate of migration of verified releases.

10) Phase 4 RFI Report for CAU WP-339 and Environmental Monitoring Report for CAU ST-341, CAU 8-28, and CAU 8-35 (August 21, 2001), p. 3-4, section 3.3.2.3: Previous Investigations;

“Previous investigations conducted at CAU ST-341 include Environmental Compliance Assessment Management Program (ECAMP) investigations and the Appendix III Phase 1 and Appendix III Phase 2 RFIs (USAF, 1995a and 1997). During the Appendix III Phase 1 RFI in July 1994, 29 soil samples were collected from five boreholes surrounding the holding tank, one borehole near the overflow pipe outflow, and one background borehole in an area away from any known or suspected sources of contamination. “During the Phase 2 RFI in October and November 1996, 72 soil samples and five field replicates were collected from 16 boreholes at CAU ST-341. Four boreholes were drilled or advanced by direct-push methods near the condensate holding tank, three direct-push boreholes were advanced along the overflow pipe, and nine boreholes were advanced or drilled in and around the evaporation pond.”

11) RCRA Facility Investigation Report Appendix III Non-Wasteline Sites, (October 23, 1995) p.18-1.

“Analytical results from the 1992 soil sample collected near the UST standpipe indicated that petroleum hydrocarbons were present in the soil at concentrations of 7,660 mg/kg and that ethylbenzene, toluene, and xylenes were present at concentrations of 52.2, 82.4, and 338 mg/kg, respectively (USAF, 1993). A follow-up visual survey by Kirtland AFB indicated that the lateral extent of soil contamination may extend a minimum of 7 ft away from the standpipe.”

Phase 4 RFI Report for CAU WP-339 and Environmental Monitoring Report for CAU ST-341, CAU 8-28, and CAU 8-35 (August 21,2001), p.3-4:

“The Appendix III Phase 1 RFI concluded that a contaminant release has occurred at ST-341. Petroleum hydrocarbon contamination extended to at least 12 ft below ground surface (bgs) near the holding tank and 58 ft bgs at the evaporation pond. Additional work was recommended to fully characterize the degree and extent of contamination at the site. …

“The Appendix III Phase 2 RFI also recommended that additional sampling be done near borehole ST-341-09 to determine the nature and extent of SVOC contamination. None of the previous investigations addressed potentially contaminated groundwater in the regional aquifer or in any perched groundwater.”

12) FINAL NON-WASTE LINE INVESTIGATION WORK PLAN (May 1994) Section 16.3, DATA GAPS (p. 142);

"Additional soil samples are necessary to define the horizontal and vertical extent of potential soil contamination at this site.”

13) EPA comment letter (July 29, 1998), p. 005-6.

“SWMU ST-341, Building 1033, Condensate Holding Tank (ST-341)The Appendix HI investigation revealed high levels of gasoline range organics (GROs) (up to 360,000 ppm) in seven boreholes. Diesel Range Organics (DROs) were also detected at high concentrations in eight boreholes. Four SVOCs were detected at concentrations exceed human health screening levels. The Phase 2 investigation included the completion of eight Geoprobe and eight hollow-stem auger boreholes. 1,1,2,2-tetrachloroethane was detected above the screening level. One Semi-Volatile Organic Compound, benzo(a)pyrene, exceeded the screening level. DROs and GROs (up to 12,000 ppm) exceeded the state UST action level to 35-37 feet below grade at the holding tank, and to 65-67 feet below grade at the evaporation pond. Jet fuel A is believed to be the predominant petroleum hydrocarbon at this site. The depth to groundwater at this site is not specified, nor is any information given concerning the proximity of this site to arroyos, etc. Kirtland should present more information on the environmental setting of this site. EPA concurs with Kirtland's recommendation that a CMS should be completed for this site. Further sampling in the vicinity of borehole ST-341-09 should also be conducted. Additionally, the extent of contamination to the east of the condensate holding tank should be determined.”

14) Questions and Answers for Fuel Leak Public Meeting:

“In early 2007, the well was installed and the fuel product discovered on the groundwater.”

15) See here. Supplemental Information and Site Summary Report for SWMUs Recommended for No Further Action (April 1999) p.5 and 6. https://kirtlandafb.tlisolutions.net/sitedocs/PDFS/16%5C1651.PDF

16) Agency for Toxic Substances and Disease Registry

“JP-4 and JP-7 may be released into ground waters as a result of seepage from contaminated soils during storage, aircraft maintenance, and fuel storage and dispensing operations (Twenter et al. 1985). A fuel layer of approximately 2 feet was identified in groundwater from shallow wells at Robins Air Force Base (Georgia) on a site where an undetermined amount of JP-4 was released into the soil from an underground fuel supply line in the 1960s (Air Force 1985a)."

17) “While fuel tanks now have gauges and modern technology that allow officials to more closely monitor how much fuel goes in and out, Kirtland civil engineer Brent Wilson says the leak dates back to the days when ‘the way to measure was to take a long stick and dip into the tank.”

Mr. Wilson fails to explain how personnel would dip a stick into a tank containing more than a million gallons of fuel.

18) Additional Requirements for Stage 1 Abatement Plan (p.2, item 3):

“KAFB must determine the full vertical and horizontal extent of the JP-8 discharges reported in November 1999. Especially in the area of of pipelines #22 and #23, sampling only along the pipeline may not be sufficient to define the full 3-D extent of the contamination. The reason for this condition is to comply with 20 NMAC 6.2.4106.C.2.”

19) Albuquerque Journal, Kirtland Jet Fuel Spill ‘Significant,’ Section E, August 5,(2000).

20) ABQ Journal, Overdue Test Finds Kirtland Fuel Leak, p.A8 (8/8/2000).

21) See p. 4, Sec. 3 2.2.2.3: Data Gaps:

“However, the sampling program should also include the goal of tagging the bottom of the plume to determine whether or not measurable contamination migration has occurred since plume boundaries were determined during earlier project phases. The current extent of the TPH plume at both site locations should be adequately defined.”

22) Comprehensive Site Evaluation of Bulk Fuels Area 4-3 September2004, SECTION 4, p.4-3

23) June 23, 2009 Ground Water Bureau letter (p. 1):

“3. NMED expects that off-base remediation activities, including both LNAPL recovery and dissolved-phase ground water remedial action, will be undertaken at the soonest practicable juncture. The proposed schedule does not reasonably accomplish this goal.”

24) Kirtland's Interim Measures Work Plan, Part I: Field Investigation Activities, and NMED's response (p. 164):

The Permittee's records indicate that it has installed and is operating "interim ICE SVE" units on the Permittee's property; however, these four soil-vapor extraction (SVE) units are not an adequate interim measure to address the existing ground water contamination, including the LNAPL plume that has migrated beyond the facility boundary. From April 2003 to September 2009, these SVE units have extracted an estimated 286,600 gallons of fuel. From April through September 2009, the average extraction rate has declined by 25 per cent. The average extraction rate for each SVE unit is about 2,975 gallons per month.

At the rate of extraction achieved so far by the existing SVE units, the operation of these units would take over 14 years to remove 2 million gallons of fuel. This length of time is unacceptable because additional groundwater within the capture zone of water utility Authority water supply wells could become contaminated before the remediation could be completed. Furthermore, should the Department's calculations prove to be more accurate than the Permittee's estimated volume of fuel, it would take of 56 years of the remediation of the fuel to be completed.

NOTE: This is a long document (558 pgs.), and dated April 2010. This began NMED's HWB assuming oversight of the Kirtland spill, managed the previous 10 years + by NMED's GWQB. Beginning on pg. 155 of this document, HWB describes a damning record of inadequate characterization and remediation. It is worth nothing that, most of what GWQB asked Kirtland to perform in the previous 11 years, has of this date (Dec, 2013) still not been done.

25) See NMED NOD (Notice of Deficiency): August 6, 2010:

"(…) Even though this release was first discovered 10 years ago, the U.S. Air Force (Permittee) has not characterized the nature and extend of Bulk Fuels Facility Spill, nor conducted adequate remediation. The threat posed by this release demands immediate and aggressive action as called for in the New Mexico Environment Department's (NMED's) April 2 2010 letter)."

See NMED NOD, Dec. 10, 2010.

"The New Mexico Environment Department (NMED) has reviewed the revised Interim Measures, Vadose Zone and Groundwater Investigation Work Plans, concerning the Kirtland Air Force Base (KAFB) Bulk Fuelds Facility Spill, Solid Waste Management Units (SWMUs) ST-106 BS SS-111. (…)"

"NMED finds the plans to be deficient, and provides the following comments."

26) See EDB plume map, p. 103. See Figures 5-13 > 5-15, beginning at page 125. See Bernalillo County Water Utility Authority (WUA) memorandum to Kirtland, notifying of WUA's intention to enlist USGS to plan monitoring wells WUA deems essential, and Kirtland has not.

27) On April 2, 2010 NMED submitted 2 documents to Kirtland. The Ground Water Quality Bureau (GWQB), which administered NMED oversight the previous 10+ years, handed oversight to NMED's Hazardous Waste Bureau (HWB). GWQB's reasons were for lack of Kirtland compliance with their guidelines. GWQB's April 2 letter said:

"KAFB has not complied with the requirements of the GWQB's first and second NOD's. KAFB has failed to provide an interim work plan with specific dates for task completion, or a revised timeline that provides for the investigation and abatement of off-base plumes in a reasonable time frame. Additionally, KAFB's December 30, 2009 letter indicated that it will not be moving expeditiously to begin active remediation of off-base contamination. Given the scope and severity of the contamination plume, KAFB's proposed approach is not acceptable."

"(…) As demonstrated by the GWQB's letters of June 23, 2009, October 18, 2009 and this letter, KAFB has not and is not meeting the GWQB's requirements. Therefore, the GWQB has transferred oversight of corrective actions at SS-111 and ST-106 to the HWB, which will enforce corrective action under the HWA and the New Mexico Hazardous Waste Management Regulations, 10.4.1 NMAC. From this point forward, KAFB shall respond directly to the HWB and copy the GWQB on all correspondence and required plans and reports related to SS-111 and ST-106."

On April 2, 2010 NMED's Hazardous Waste Bureau (HWB) submitted notice to Kirtland henceforth, HWB was directing oversight of the fuel spill:

"(…) Date submitted by Permittee (KAFB) show that the contamination caused by the Buylk Fuels Facility Spill represents a significant threat to human health and the environment, particularly to well water in urban neighborhoods adjacent to Kirtland Air Force Base ("KAFB"). Despite the fact that this release of hazardous constituents was first discovered 10 years ago, the Permittee has not completely characterized the Bulk Fuels Facility spill, nor conducted adequate remediation."

"(…) Additionally, in accordance with 20.4.1 NMAC incorporating 40 CFR 264.101 c, the Permittee must implement corrective actions beyond the facility boundary".